Decided to add this to my site for whose of interest since I spent amount of time producing this.

Memories of Paul Bugl by Ronnie Tribe

I have been asked by Luis Petersen if I would like to add a chapter to his history of Paul Bugl. These are my personal memories of my short acquaintance with Paul Bugl and the Bugl boys who flew his motors and the “MOSKITO” models.

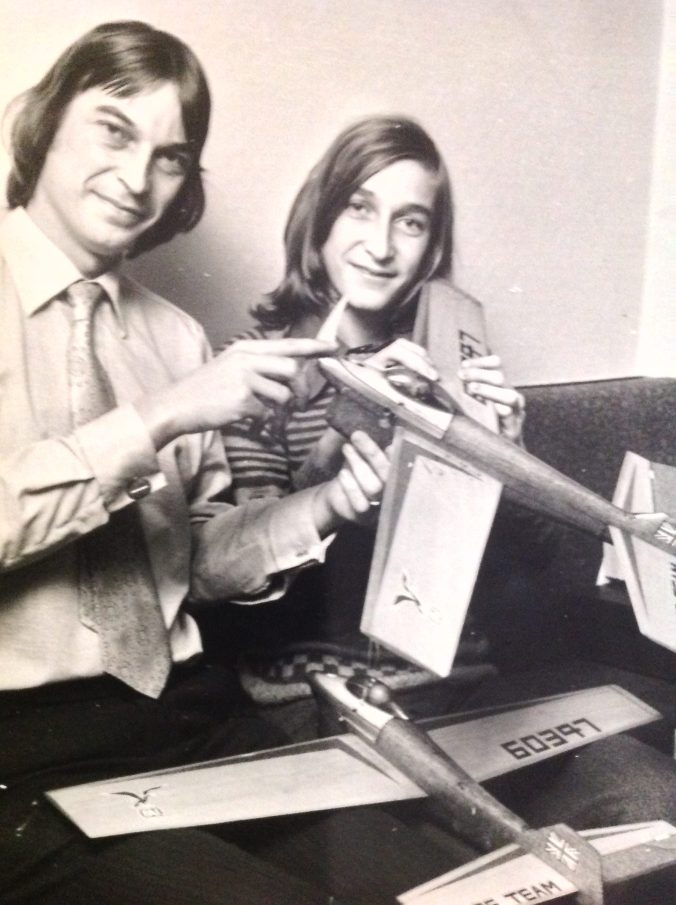

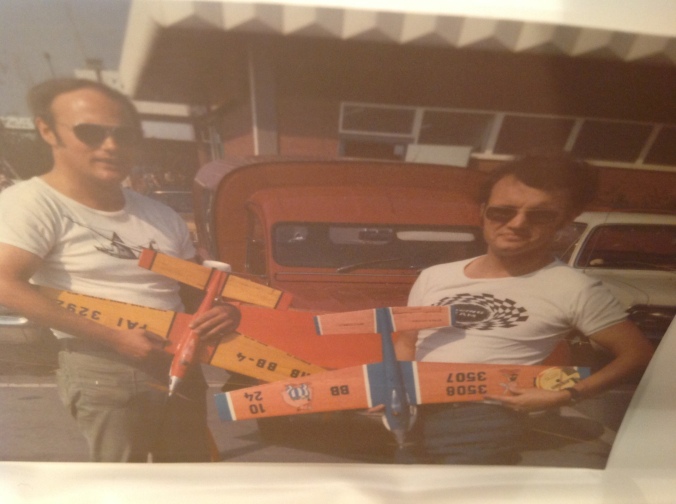

To start with just some background, I started flying Goodyear with my brother Micky and progressed very quickly into the Team Race world in the 1970’s using ETA 15’s and MVVS TRS motors supplied by Jurgen Bartels. We first ordered our two Bugl motors as a result from Paul’s advert in the Aero Modeller, later on in the year one motor and cut-out turned up in the post, I built two balsa models based on a Russian design covered in coloured tissue paper and then entered the team trials for the next World Champs to be held in Czechoslovakia 1974, we were successful and here the story begins.

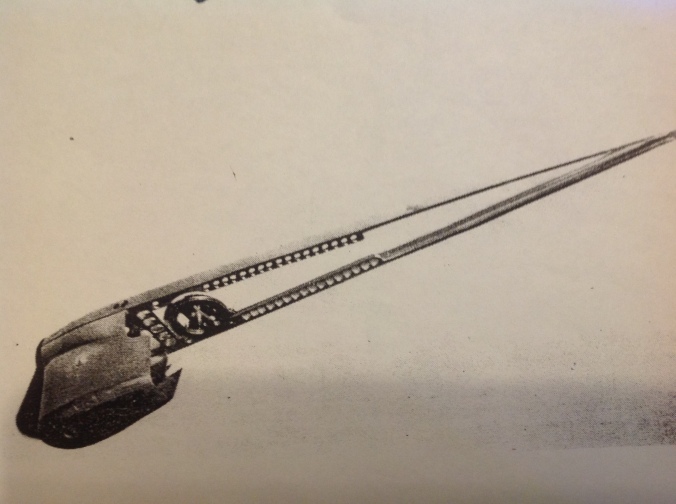

Just found one of the original pans we used, lost for many years cannot remember where it came from.

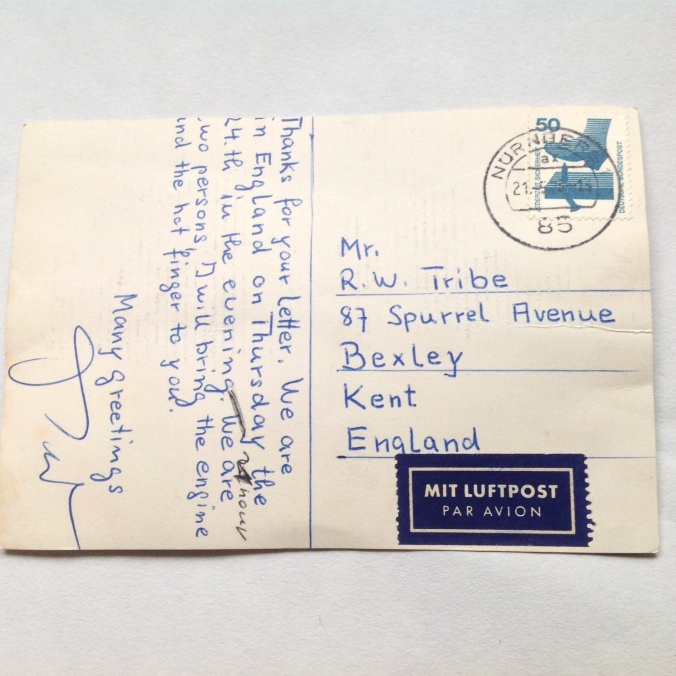

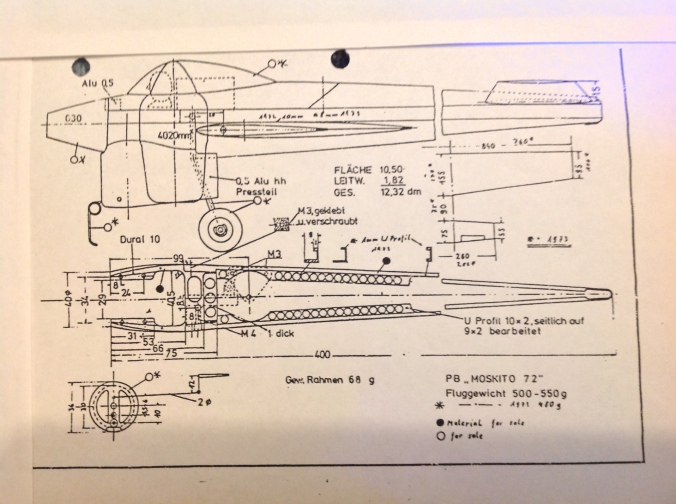

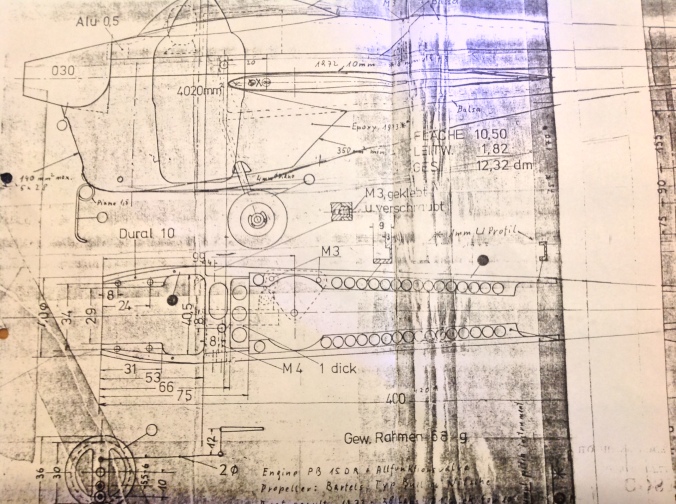

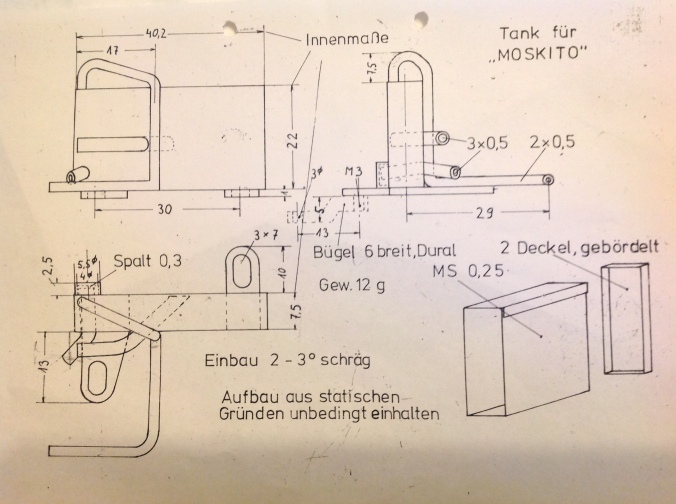

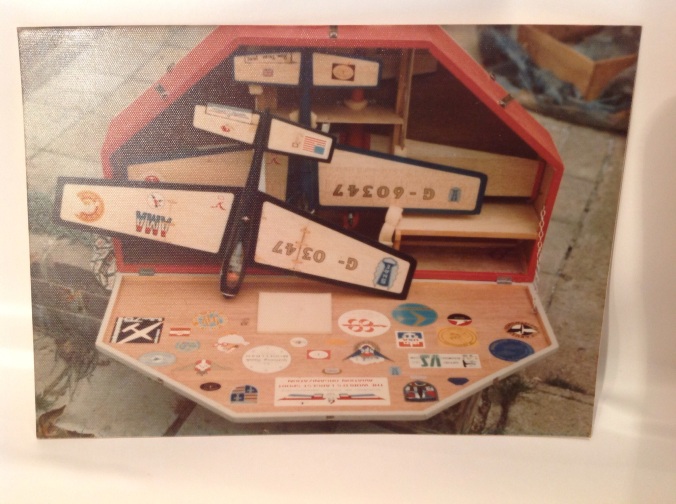

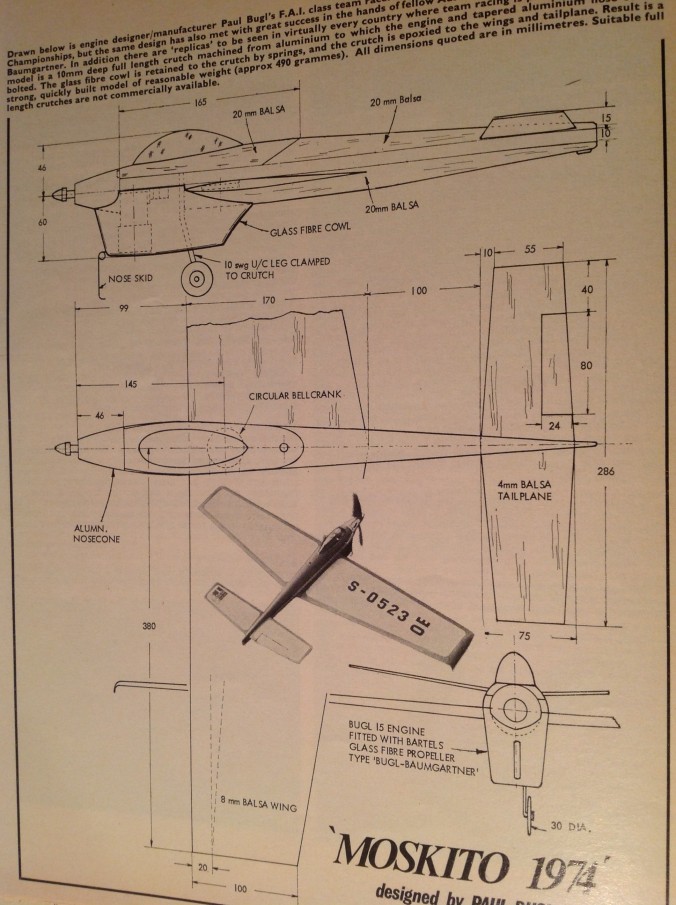

We now formed a friendship with Paul and communicated with him regularly, Paul asked if it was possible to enter the next British Champs and this was arranged, the next thing that happened was I received a post card from Paul informing us he would attend with Hans Straniak his pit man, they turned up at my Mum and Dads house which they used as a base for their stay in the U.K. This was the first time I had met Paul and Hans and the first question was to us was “How much does it cost to go fast on the Motorways” i.e Speeding fines. Paul showed us his “MOSKITO” model and gave us a copy of the plan, he also brought along the second motor and finger valve he asked us if we had taken the motor apart to see the inside workings, he was astounded that we had not and then proceeded to strip the motor to show us the internal workings including the drum system. Both Paul and Hans seemed to be very nice people with a wealth of knowledge on team race and were only to happy to discuss information, this was the beginning of a long friendship between both of them and my family.

Paul with my Mum and Dad.

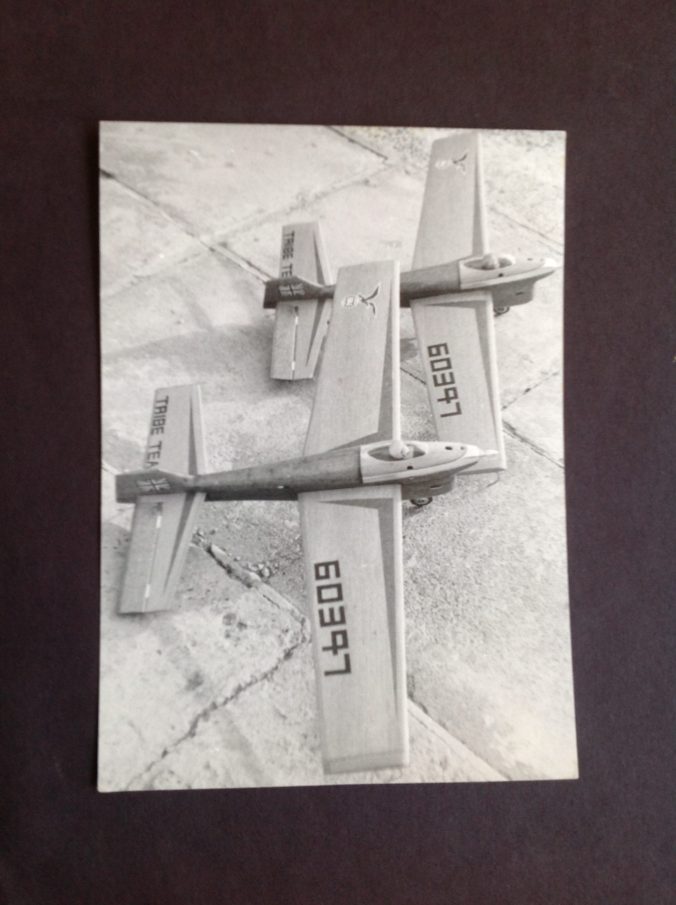

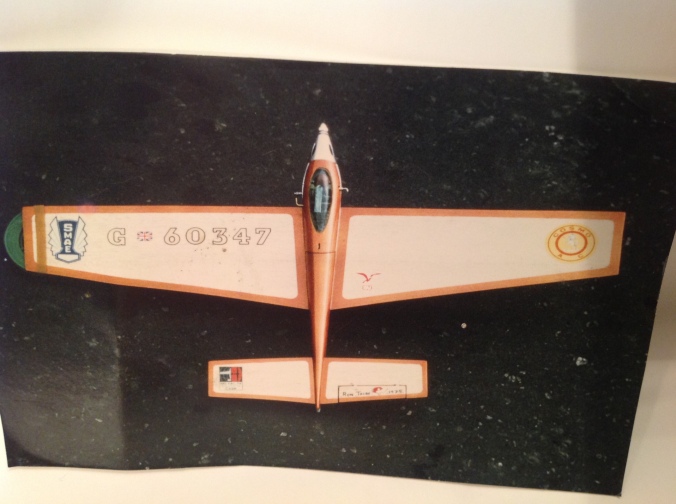

The next step was to order Two “MOSKITO” model kits to build his models these comprised of all the metal work less the fibre glass cowl, these parts turned up and two models were completed for the World Champs, these were fitted with my own fibre glass cowl fitted with cooling ducting inside. At the World Champs Paul looked at the cowl and said throw all the ducting away and just have a hole in the front and rear, on the return from the Champs the cowls were modified and a immediate improvement in consistency was obtained.

Side view of model with cowl.

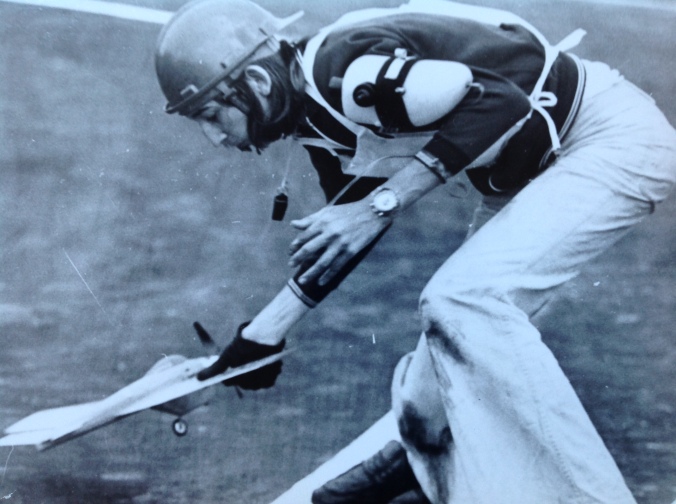

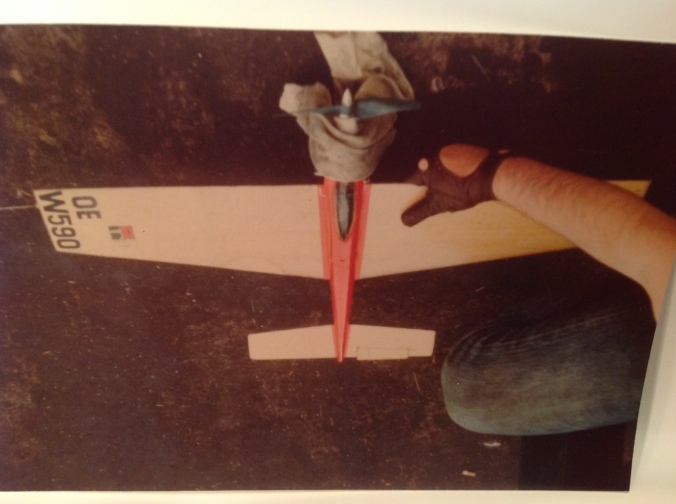

The next problem we seemed to have was with range and the motor cutting out on take-off. Without going into to much detail we arranged to meet Paul and Hans a few days before the Austrian International at Kraiwiesen where they were both practicing both Paul and Hans spent time with us showing how to setup and run the motors in competition. Basically the motors were warmed up on a rich needle setting and only leaned out for 5 seconds at the 10 second signal then the needle was returned to the rich setting for the last 5 seconds. The needle would be returned to the flying setting and at about 10 seconds to go the prop would be turned back and forth to get a fresh charge into the motor, at about 4/5 seconds the tank would be filled and at the Go signal the prop hit and the model should be gone and airborne, also you must never run the tank dry as the motor will cut-out on takeoff due to no fuel in the cut-out. I did some practicing with Hans as the pit man and decided at one stop to see how fast he was, I landed the model very fast and this is what happened, he caught the model, he was filling the tank in the air and as the model was put on the ground it was started and airborne, I had not even got the handle on the white line, I nearly fell over he just looked at me and laughed. I still think Hans was one of the fastest pit men. Another point Hans made was Paul had made the fastest motors ever however it was impossible to restart them.

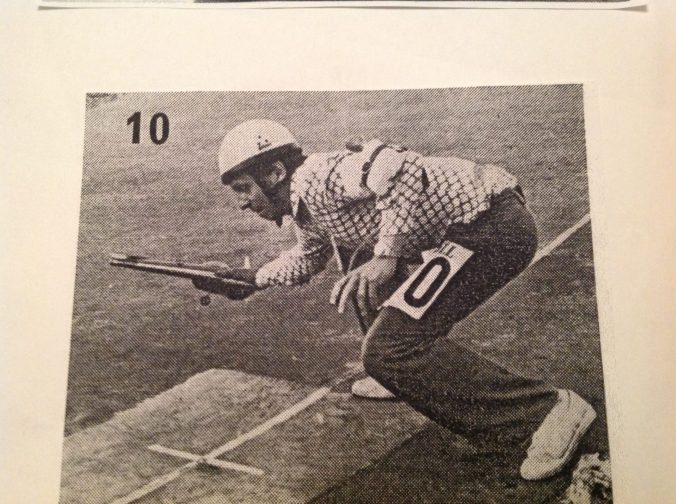

Baumgartner warming up his motor, note his thumb adjusting needle valve and stop watch on the ground.

Baumgartner warming up his motor, note his thumb adjusting needle valve and stop watch on the ground.

Hans and Micky at work.

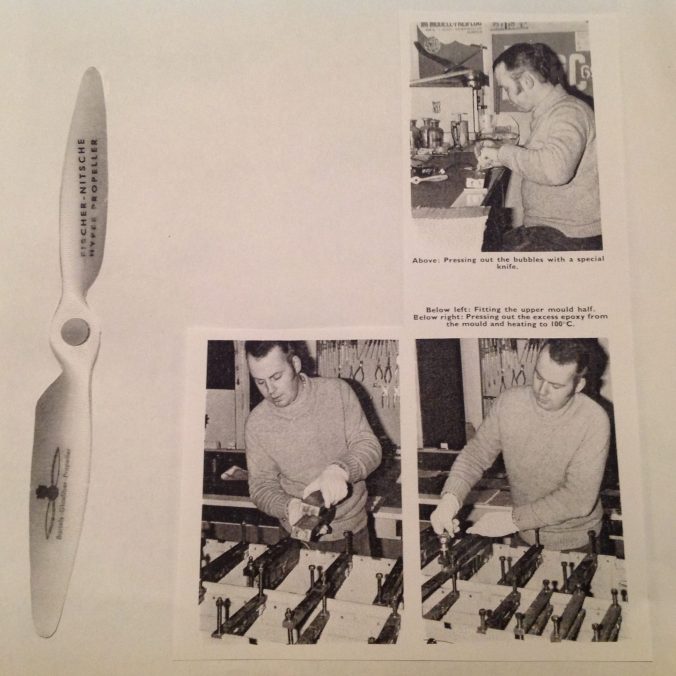

So there we have it Paul had a motor and model combination which worked very well in contradiction to all know conventional ideas in team race with many/many people questioning whether he was right or not. We continued to use his motors and models with good results ending up with the ultimate retract model however this was rather heavy, I did make normal balsa models without the metal crutch system for comparison but these showed no improvement over the original “MOSKITO” another factor which I did not realise was the number of flyers using Paul’s motor and models in Europe. There is one other person I must also mention this is Jurgen Bartels who made nearly all the fibre glass propellers used by these teams. These ranged from the classic Drazek-special 7×7 1/2 through to the BUGL-BAUMGARTNER and the FISCHER-NITSCHE propellers.

Last “MOSKITO” with streamlined bottom and very light cowl.

Heaton / Ross Bugl model from Eurochamps 75, very similar side profile to Bugl Moskito above, note Tribe Bros prop.

Two other photos of the same model.

Just to show accidents did happen, I was flying in a very windy competition when I passing someone who was very tall, the wind picked up his anorak hood which blew up and the hook went into my down line, a chance in a million of this ever happening.

I visited Paul many times mainly on-route to competitions, the first time was when he was still living at his old house, myself and Jim were going Skiing with Metkemyer and other Dutch flyers and their wives to Austria, we met up with Hans and his wife and they showed us how it was done? I cannot remember much about his house apart from the Rover 2000 car parked outside full of rubbish, when I asked Paul the reply was it kept breaking down and he was going to get the local council to take it away, so much for English engineering.

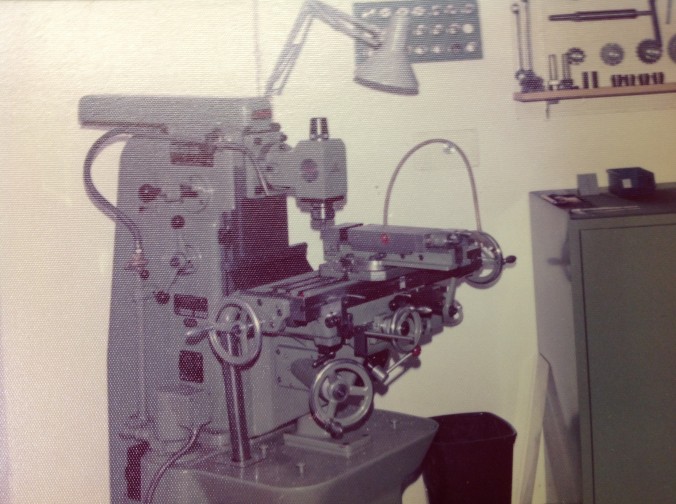

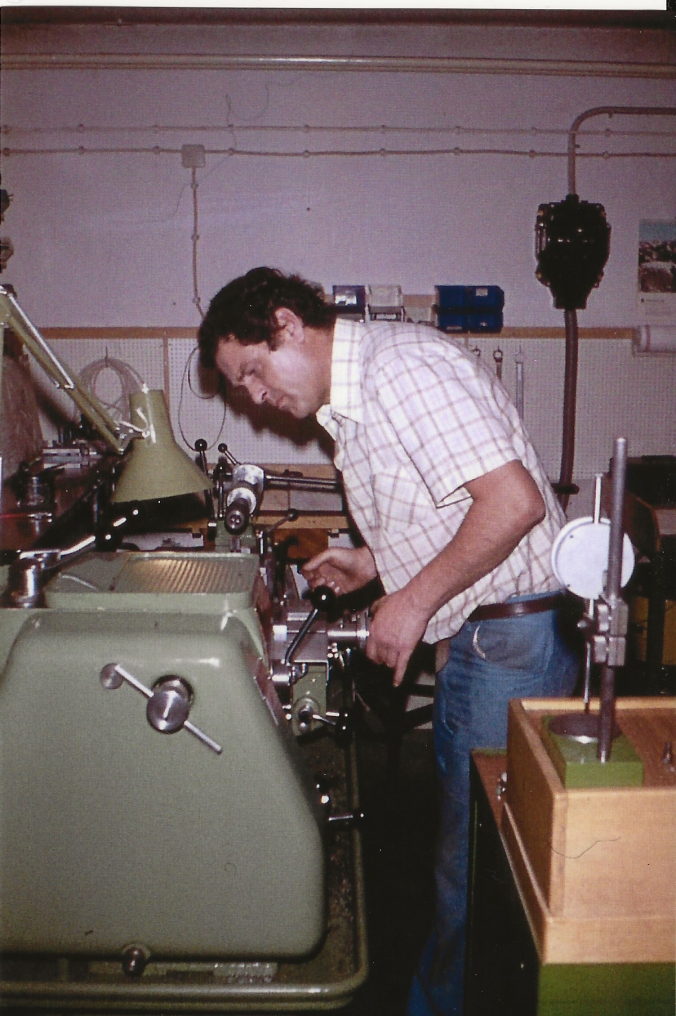

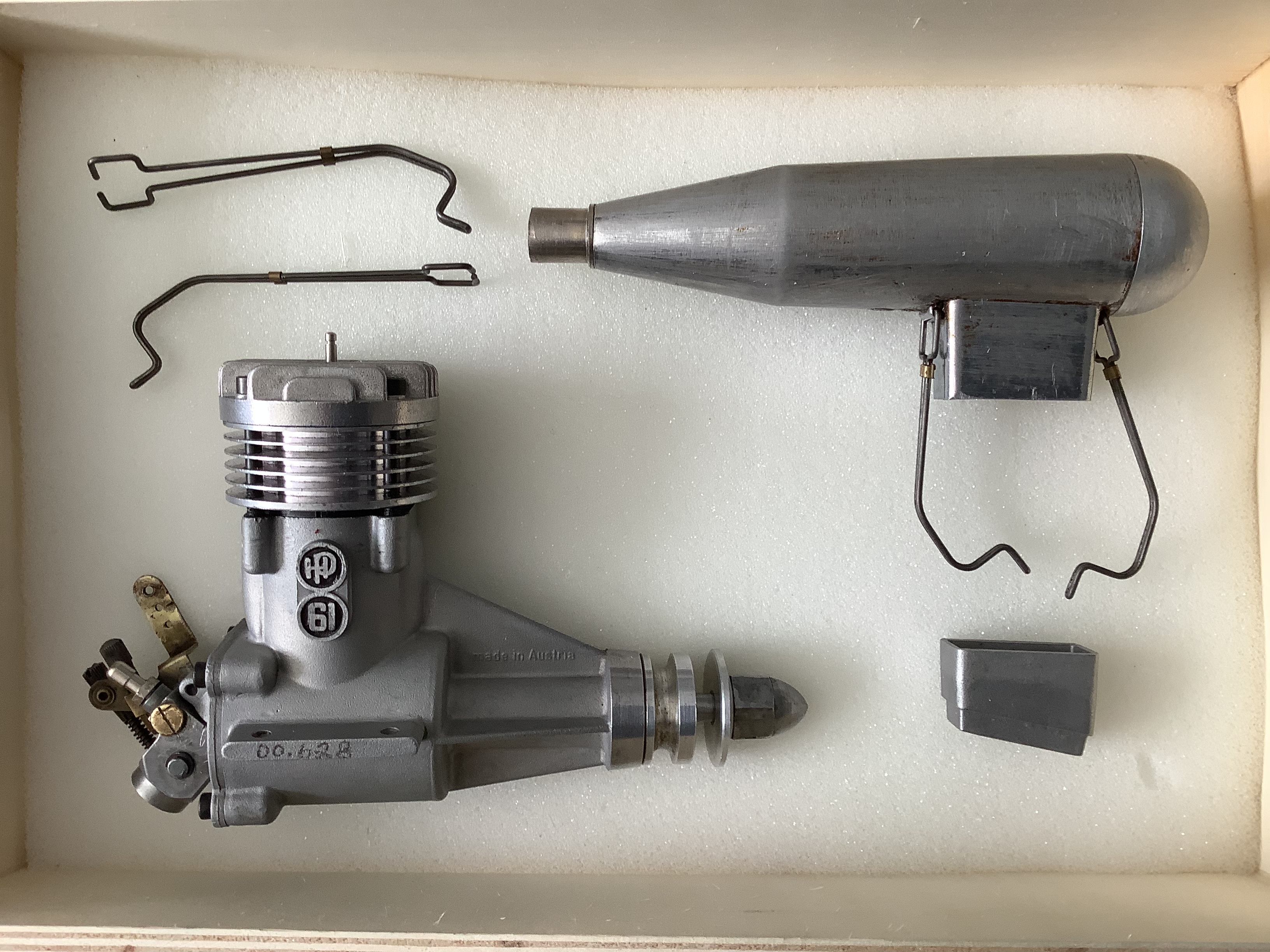

All my other visits were to his new house at “Moosbach” right in the middle of nowhere not far from the East German boarder it used to annoy Paul the sound of American helicopters flying up and down. The house was purpose built with a garage and workshops in the basement, first floor was for living accommodation and the top floor with a bedroom at each end and room for a full size snooker table to be added later. Motor testing was undertaken across the other side of the field in a corner of a wood, another point of interest was Paul now owned 3 cars guess what “Skoda” Paul said they were the most reliable. When we used to stay overnight we would sit outside on the veranda and listen to music another passion Paul had was to look at the stars and planets through his telescope.

Front view of Paul’s house under construction.

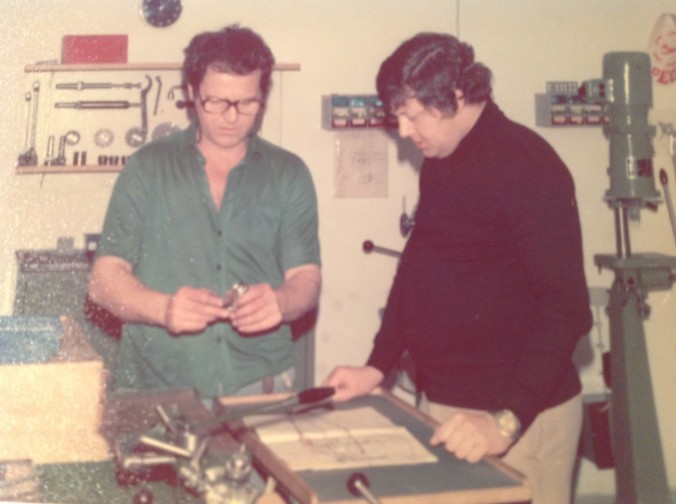

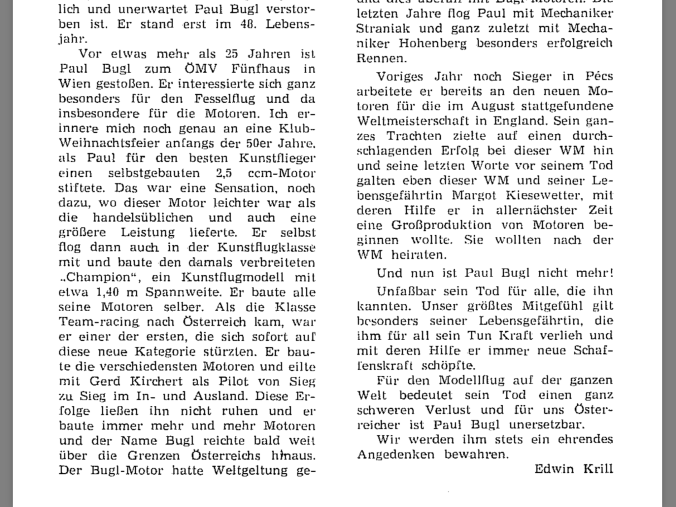

December 2022. Jan van der Kroon sent me these photos of them working at Paul’s on two engines about 1975-1978 note the tray of Mk 2 cases. Thanks.

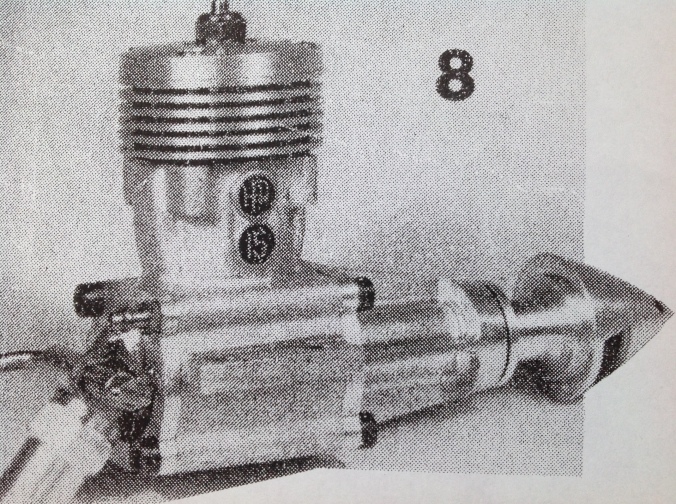

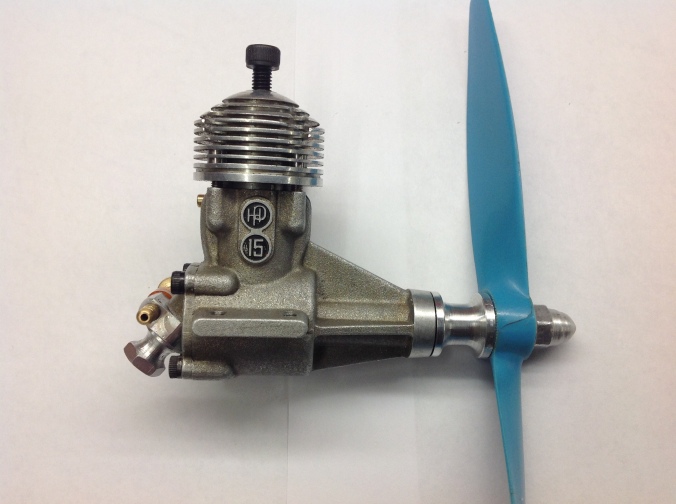

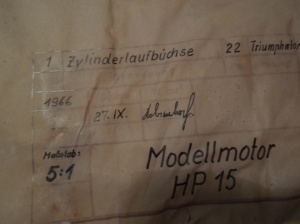

We often discussed motor and model design, so far no mention has been made about his time at HP and his HP motors. Paul did discuss some of his time at HP and here are some of the facts I believe, I cannot confirm these but I think there is some element of truth in them. Paul was employed at HP to design and manufacture motors for large target aircraft for the military, at the same time he used these facilities to start-up production of the HP 15 and HP60 radio motors for commercial sale. This is where the story gets very confusing and not very clear, as I understand Paul went on holiday and while away the auditors carried out progress checks and found only limited sales for large investments i.e the grinding machine for the bell drums for example (thousands of DM). Paul never returned to HP. A limited number of HP 15 motors where completed for team race and a few speed motors. The team race motors preformed very well winning many major competitions, obviously Paul had a winning design with his HP15 which would make the basis of his next project Bugl motors. The only HP15 I have seen is owned by Hans Straniak this is new complete with cut-out and un-run in a clear plastic box very similar to the Cox 15 box. Another point of interest was Paul told me about the time they visited Pec’s for the Hungarian competition with their HP15’s I think they won, however when they came down from the hotel on the following morning to return home the cars had been broken into and all the motors and models stolen? The Russians were also at this event maybe this is another story?

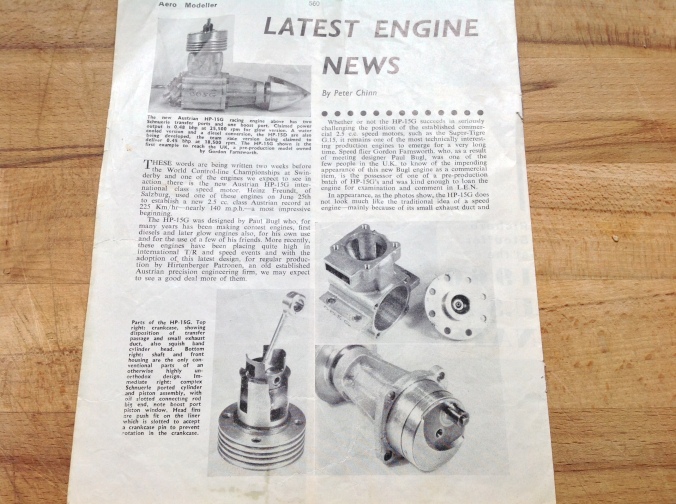

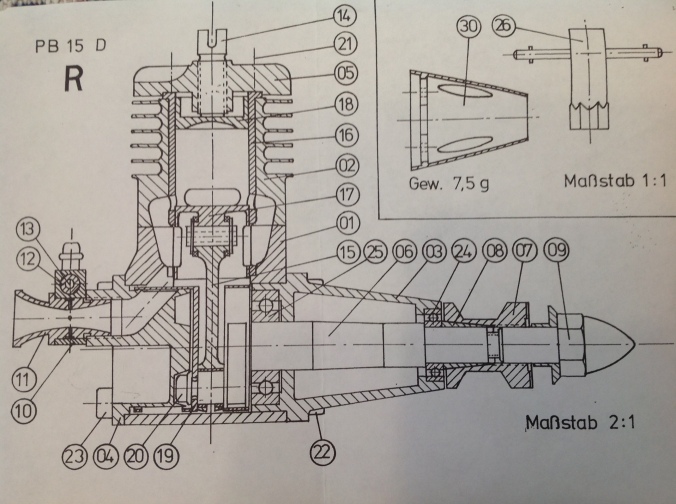

HP 15 motors were before my time but I think this is worthwhile to give a bit more detail on Paul’s motors.

Feb 2021. Just received the following information from Christian Hirsch in Austria with the following photos, the first photo shows a team race model and motor purchased from Paul in 1960 and photos of two marine motors made by Paul the first is the HP 15 and the second a HP Prototype for class FSR 1967.

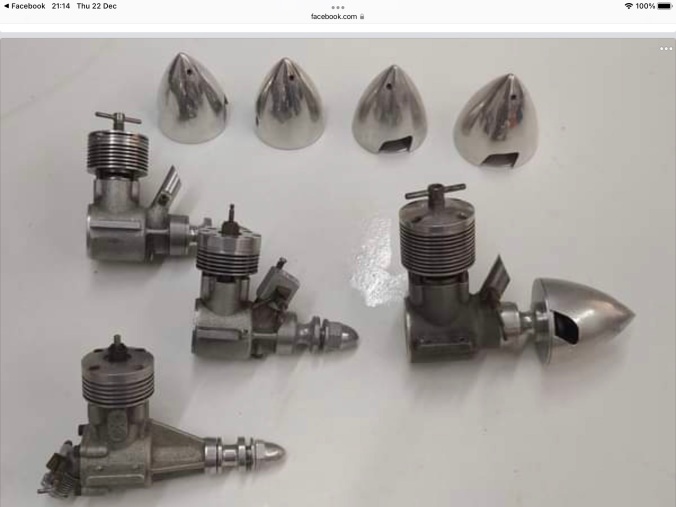

Two more photos of Bugl 2.5 motors and 5.00 cc motor and HP15 glow from Wolfgang Habe thanks. I did discuss the 5.00 cc with Paul and what I remember this was made for a 5.00 cc class of racing which never happened never seen this motor or know how many were made.

December 2021 update. Following on from the above, Ref my photo of the original Bugl motor and model there seems to be some conjecture as to whether this motor is based on a Oliver Tigre or Paul’s design to my best of knowledge this is a original motor and not copied from any other motor it is still owned by my friend in Austria I leave it up to you to decide.

These motors were used in the World Champs in Kiev 1962

Team Race. Richter/Turk. Bugl/Kirchert.

Speed. Freundt

Also these types were flown by Vaclav Horcicka in Contest Power free flight in about the 1960s, motor info Bugl 2.5 FF 61 D.

January 2022. Been doing some more research on original Bugl motors found this web site with a index of Bugl motors see http://www.meca-region16.de look under Motoren index worth a look, also found this motor made by Baumgartner who flew team race for many years and was a were close friend on Paul’s see photo, this looks like it could be part of the jig saw from the original motor to the HP 15 design only an idea anyway. Ronnie

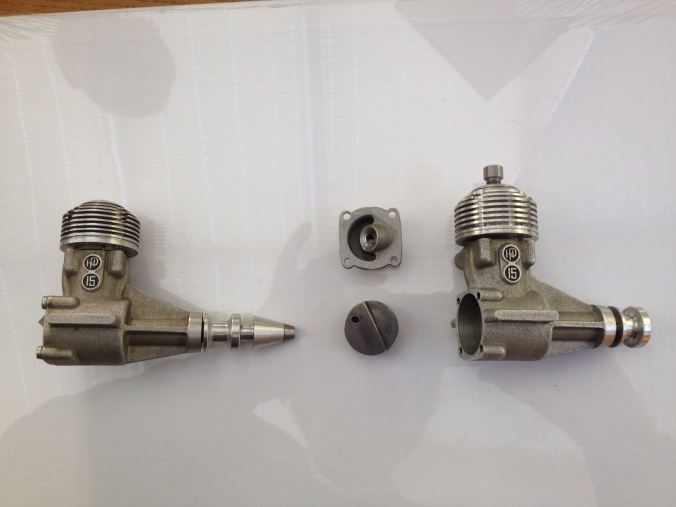

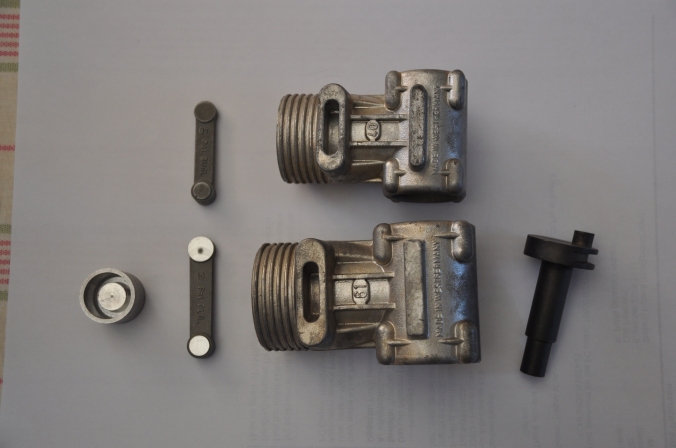

Just found this Photo. managed to get these two motors they need a lot of work and spare parts as the motors are incomplete.

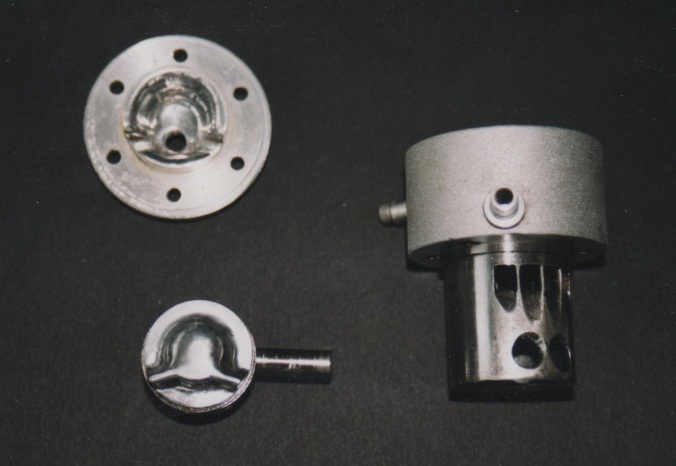

Inside a HP 15 nice.

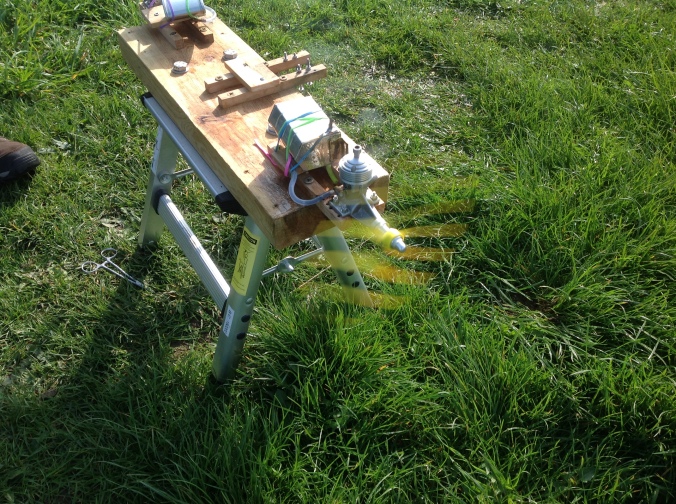

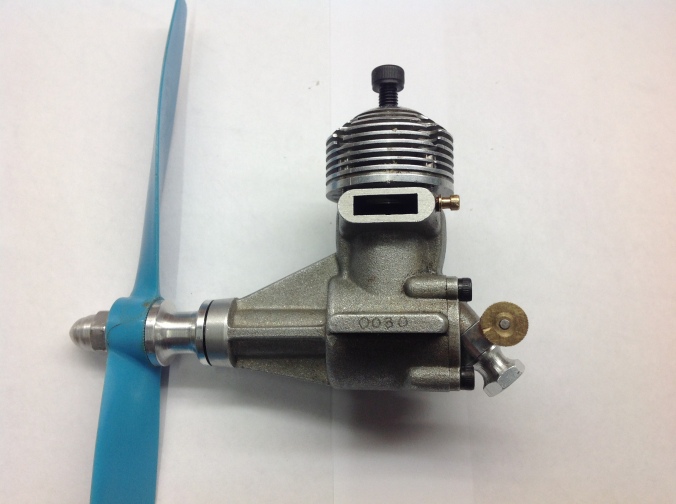

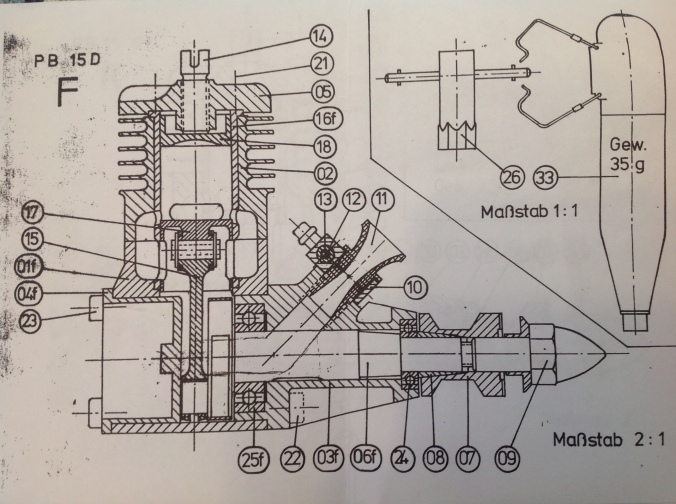

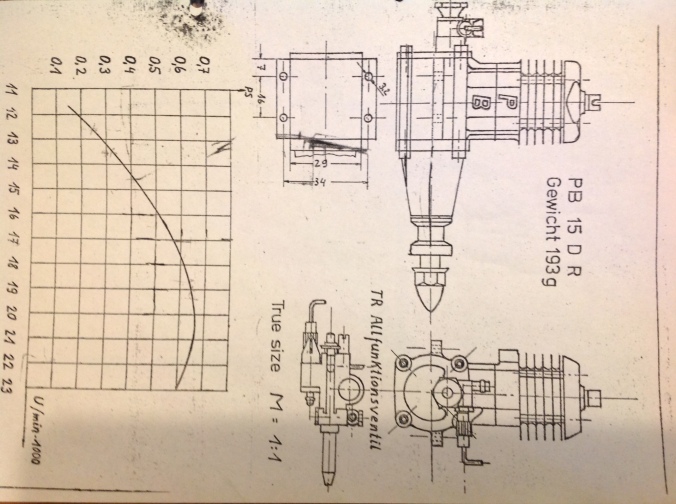

Test running the above engine after 50 odd years, new piston pin and liner honed, new prop driver and nut plus carburettor assembly. This motor has a serial number of 0030 and is fitted with a Titanium con-rod which Paul told me these were made for the Worid Champs held at Helsinki.

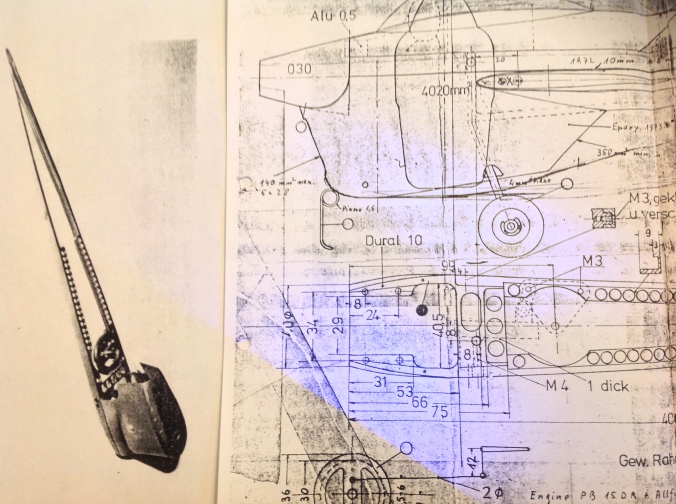

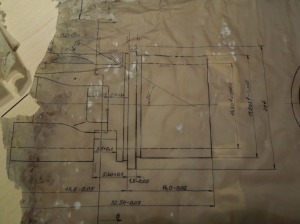

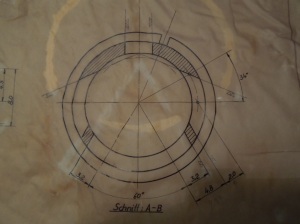

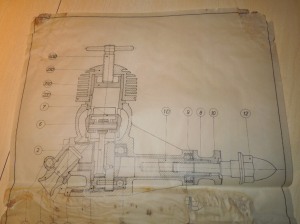

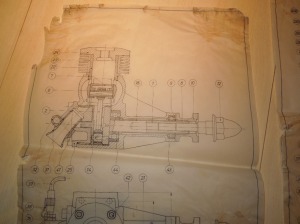

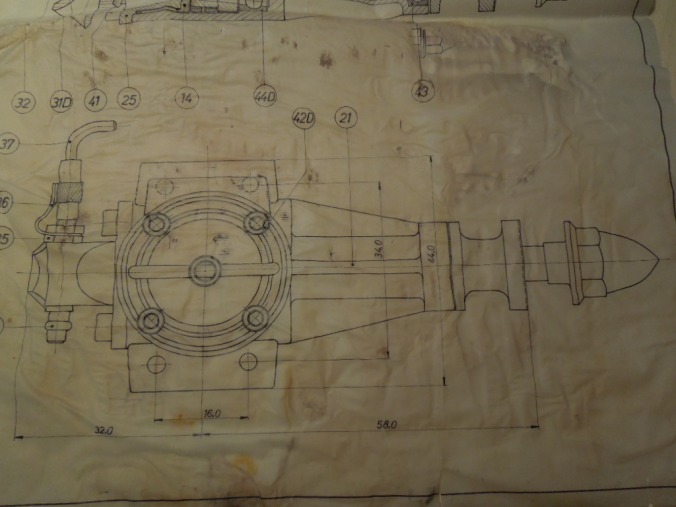

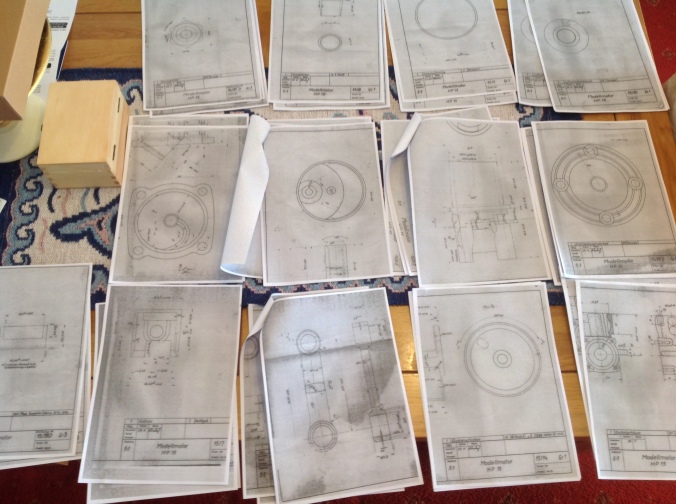

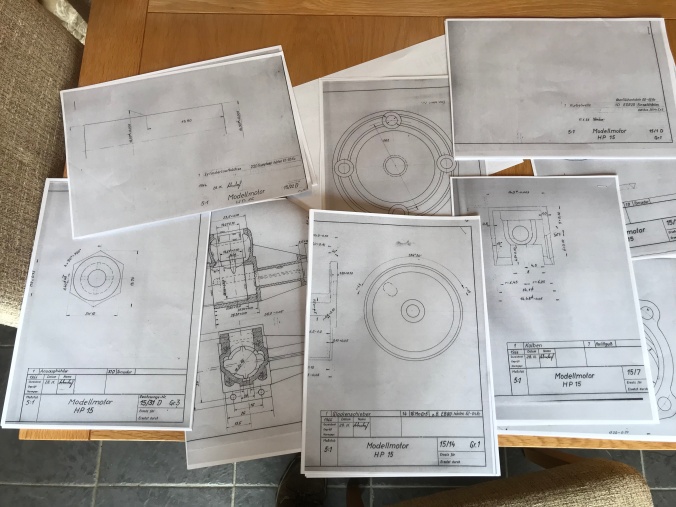

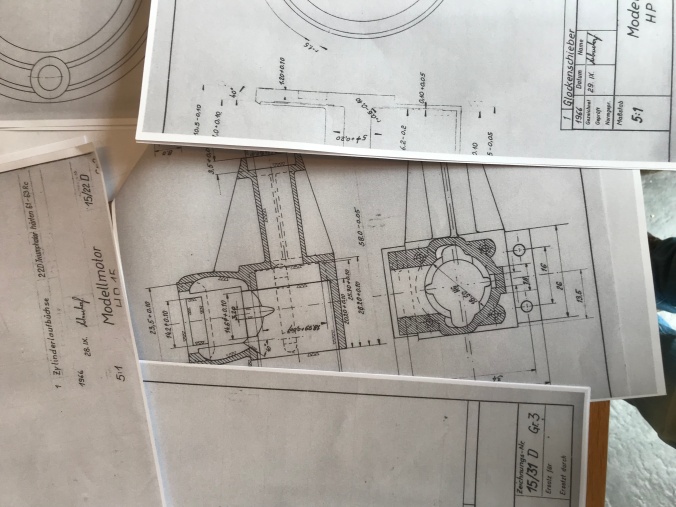

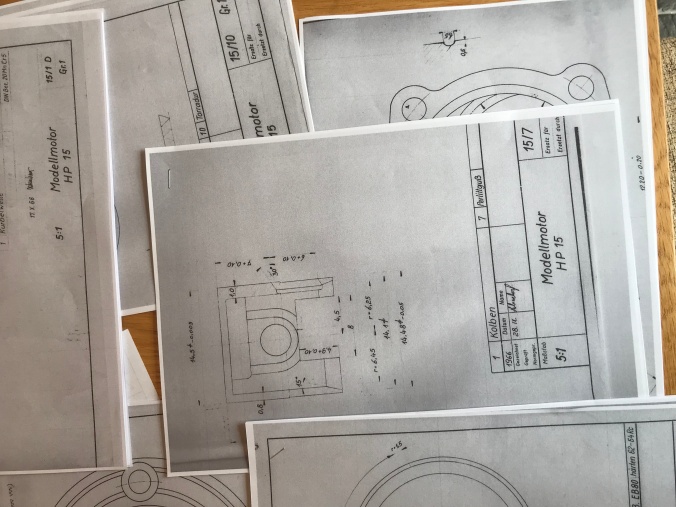

A very kind Gentleman from Austria sent me these copies of the original HP 15 drawings so I could use them to make replacement parts, these are the only know drawings in existence.

We now have a complete set of drawings.

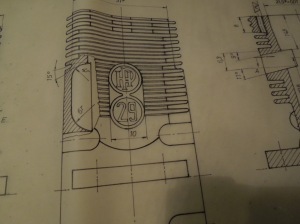

Peter also sent me photos of his HP motor collection which includes a drawing of a HP 29 which was never put into production, all these motors must owe their pedigree to pauls work at HP.

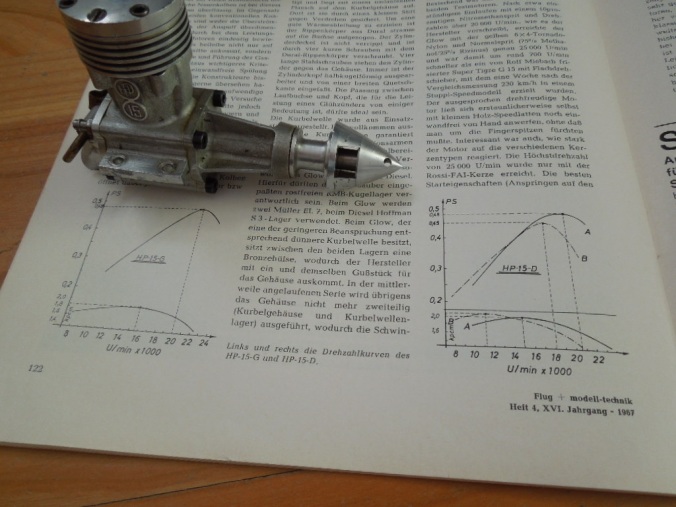

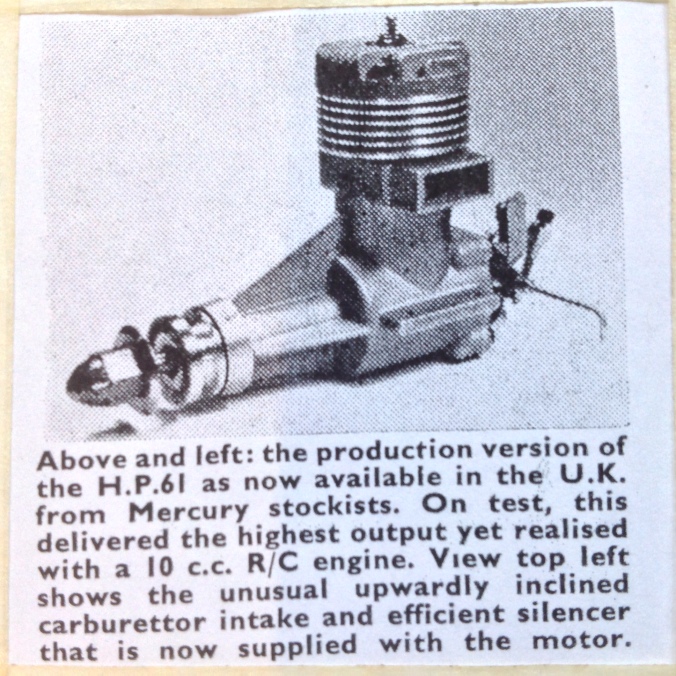

Feb 2021 article engine tests 1967.

December 2021 update. Paul Cameron sent me the attached photos of his HP15 he got from Bader/Karl at the 1972 Nats I believe, this motor has been modified which includes the different fins on the head which look like the glow motor type see photo I have sent Paul a copy of the drawings for the diesel head which he has now made see photo.

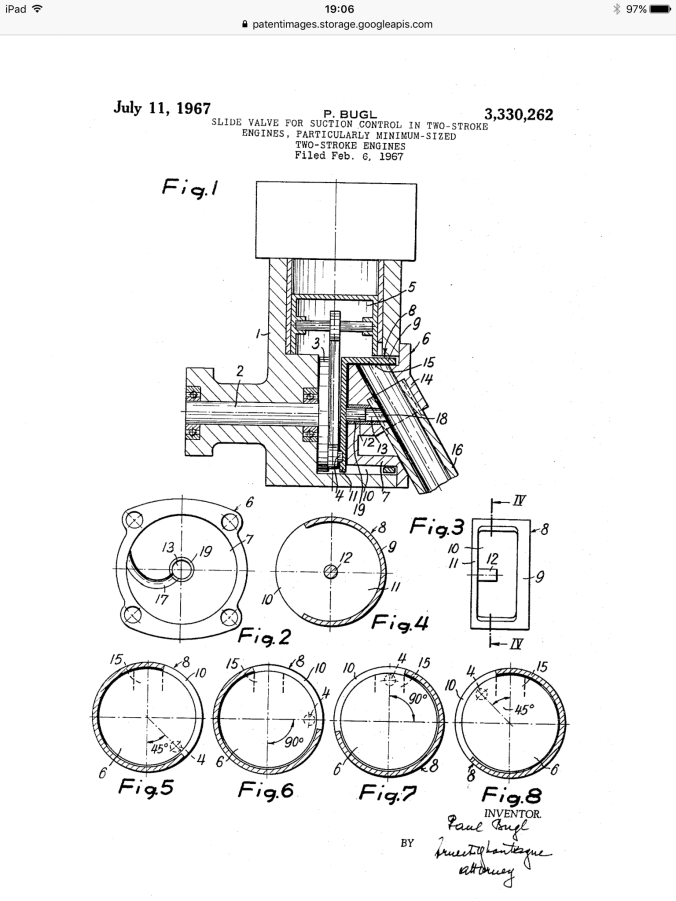

Only photos I could find of the HP 60.

After this Paul seemed to disappear off the scene for a few years, I can vaguely remember him saying he had been to or working in East Germany at a motorbike factory helping with tuned pipes and carburettor design? I remember one night Paul discussing the optimum length of a carburettor nearly the length of the model. Paul also showed me his RC carburettor design, the carburettor had a slot cut from the top to the bottom on one side, a metal spacer the same shape was inserted with a hinge pin at the bottom, by moving this metal spacer in or out you could control the speed of the motor. Anyway the next stage was the Start of Bugl motors, many prototypes were made long and short shafts, with or without boost ports ending in the production models MK1, MK11, and finally the MK111 and “MOSKITO” parts including the retract model.

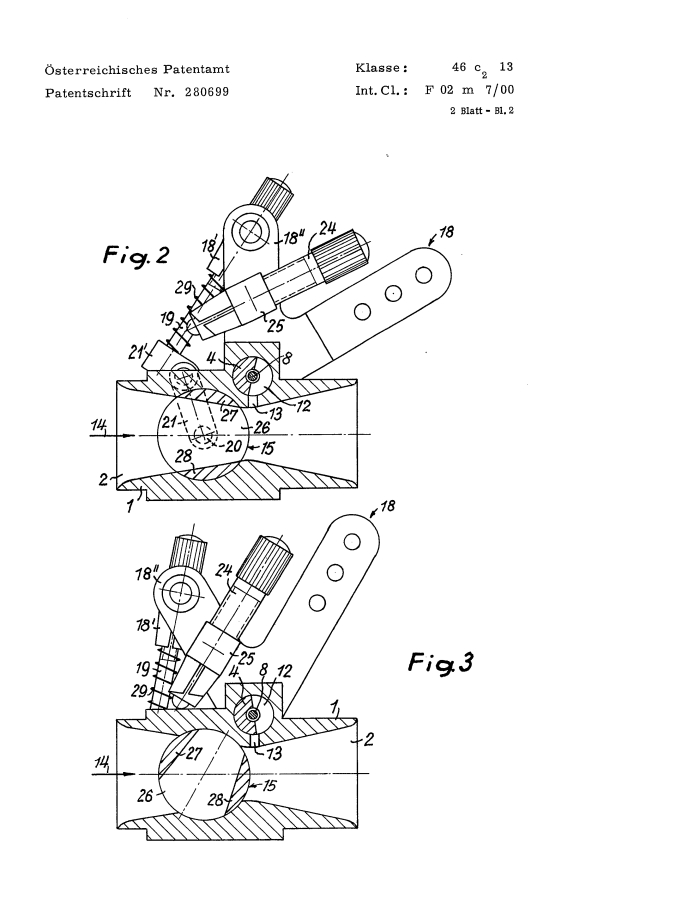

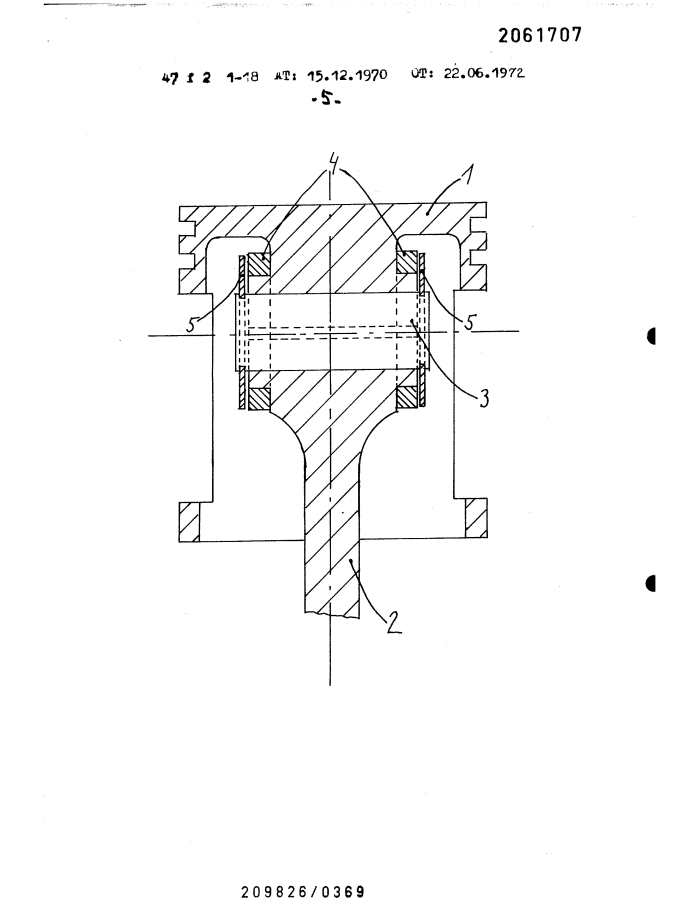

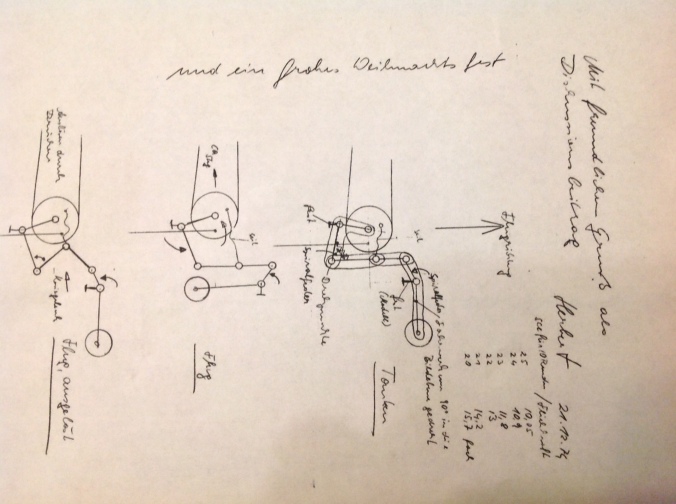

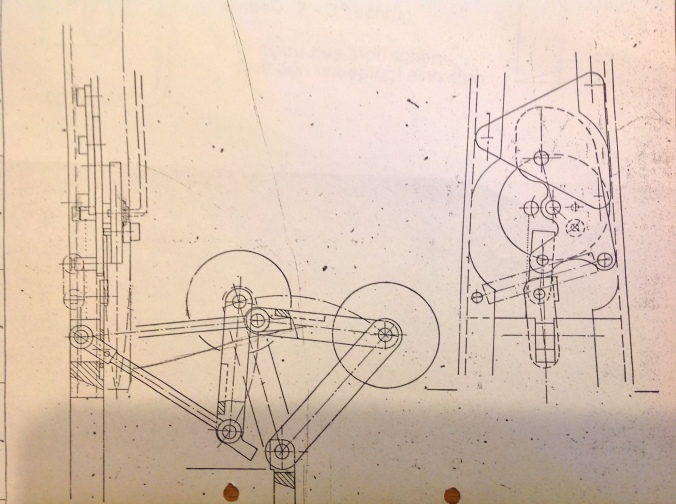

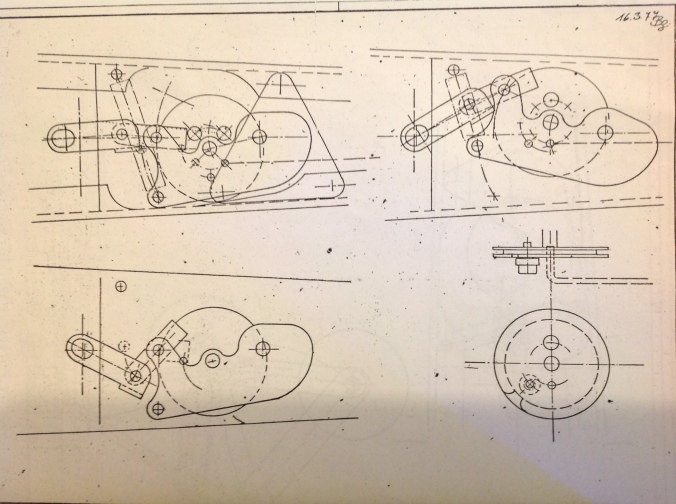

2021 March. Just found these drawings of the RC Carburettor in the Patent office.

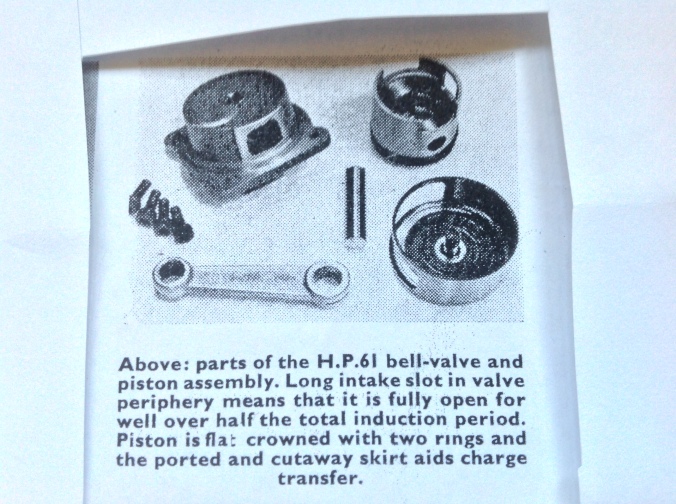

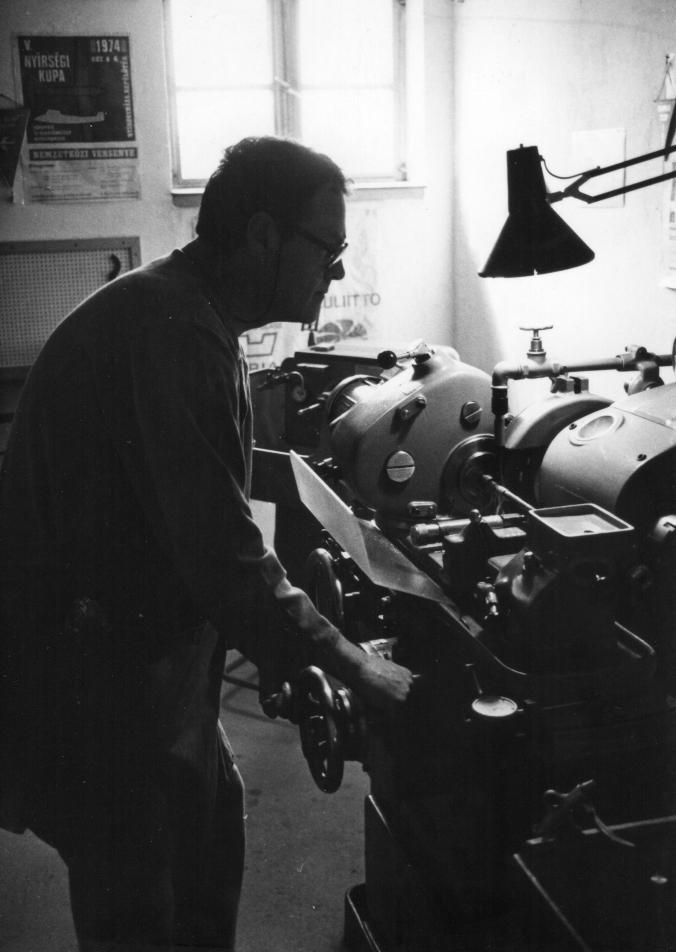

December 2021 update. HP 61, I have been looking for one of these motors for many years without any luck to join my small collection of Bugl memorabilia, one motor came up this year on e bay this looked in a terrible condition like it had been at the bottom of a lake for many years it only cost me fifty pounds so I was happy with this, the motor was in a terrible condition would not move rust all over bearing would not turn I say no more, anyway after a lot of time and heat I managed to get the motor apart, Luis sent me some parts and Alan added new bearing and cleaned up the motor, this motor is an early version as it has only one ring compared to the later ones which have two rings and a different rod, the motor now looks in first class condition and a valuable item to my collection.

Prototype serial number 07

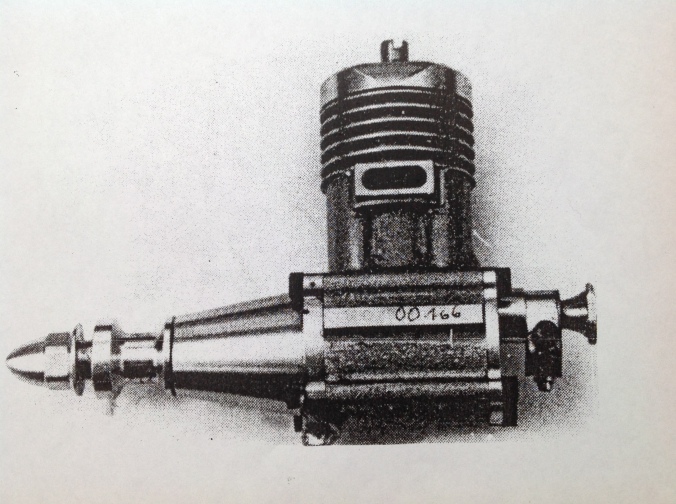

This motor serial number 00166 was used by Heaton Ross at the world champs at Hadrek Kralove in 1974 setting the fastest time in the world at that time of 4.04. I understand from Malcolm this was a 2 port design and could have been a pre-production version this motor is now in the collection of Henry Nelson.

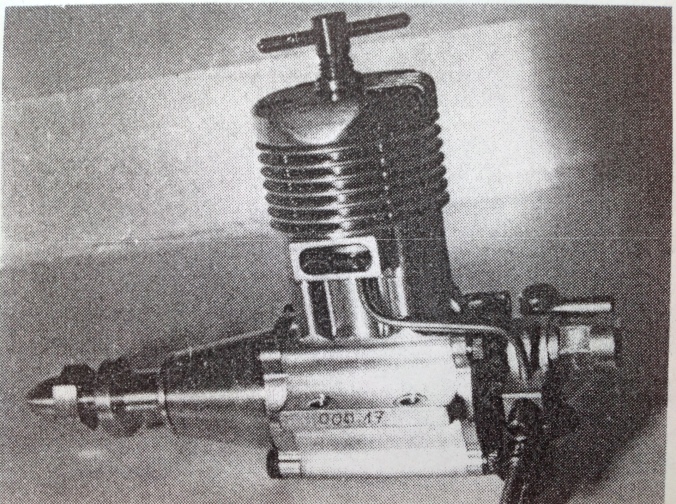

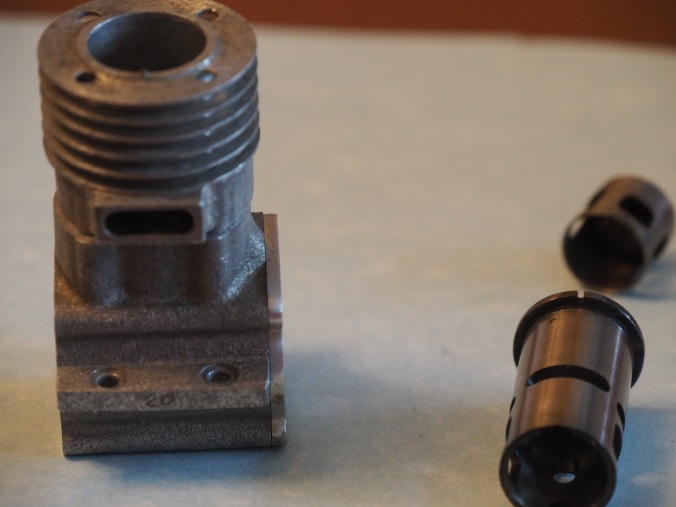

The above motor was also a pre-production version with the serial number 20, this crankcase did not have the PB motif this was added on later motors it also had a very small boost port. Photos from Malcolm Ross.

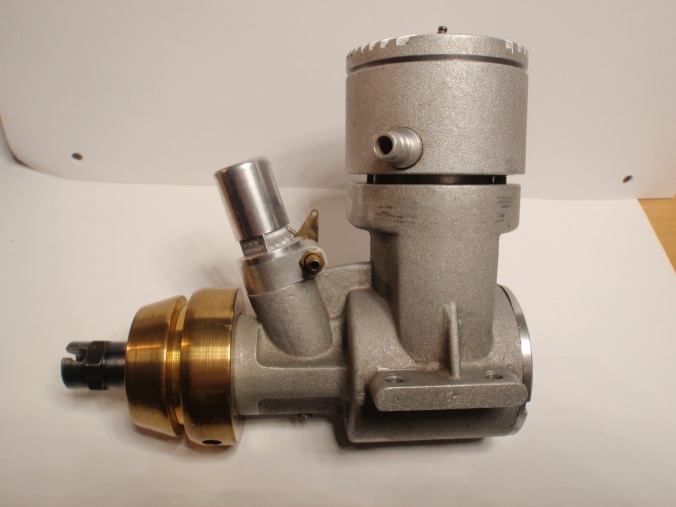

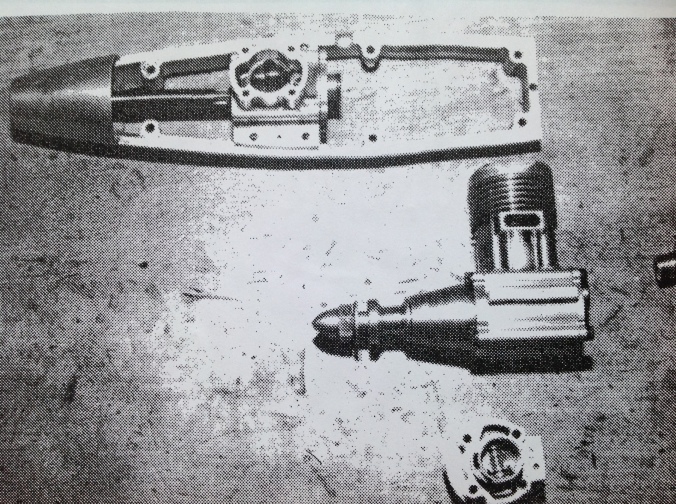

MK1 with parts.

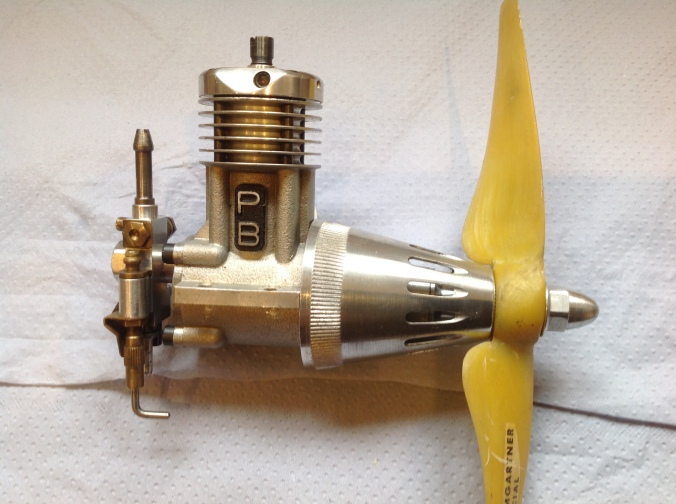

MK11 with cut-out.

MK111 last of a few.

Piston tools

2021 March. Copy of drawing held by Patent office on Paul’s connecting rod small end.

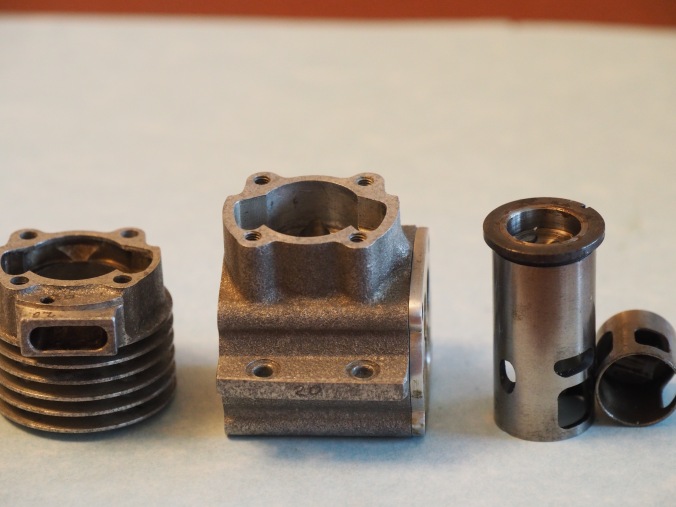

MK11 castings ready for machining.

Case and cone machined.

MK 11 motors nearly ready for dispatch.

Interesting photo of a MK 11 motor which was modified by Malcolm Ross by fitting his own HP 15 type drum valve induction system, the motor ran very well winning the British Nationals.

Bugl Tool Kit. Comprises of Drum and prop driver tools, ball race bearing fitting tools, set of carburettors from 2.9 to 3.4 mm and the pin and cir-clip remover for the little end.

Retract model. Note the large diameter comp-screw this fitted into the contra piston the idea being to help cool the top end, this did improve the speed varying between 0.2 up to 0.4 seconds for ten laps before the advent of the push pull Head design.

Years ago we would say designed on the back of a fag packet.

Paul also made a few front induction motors.

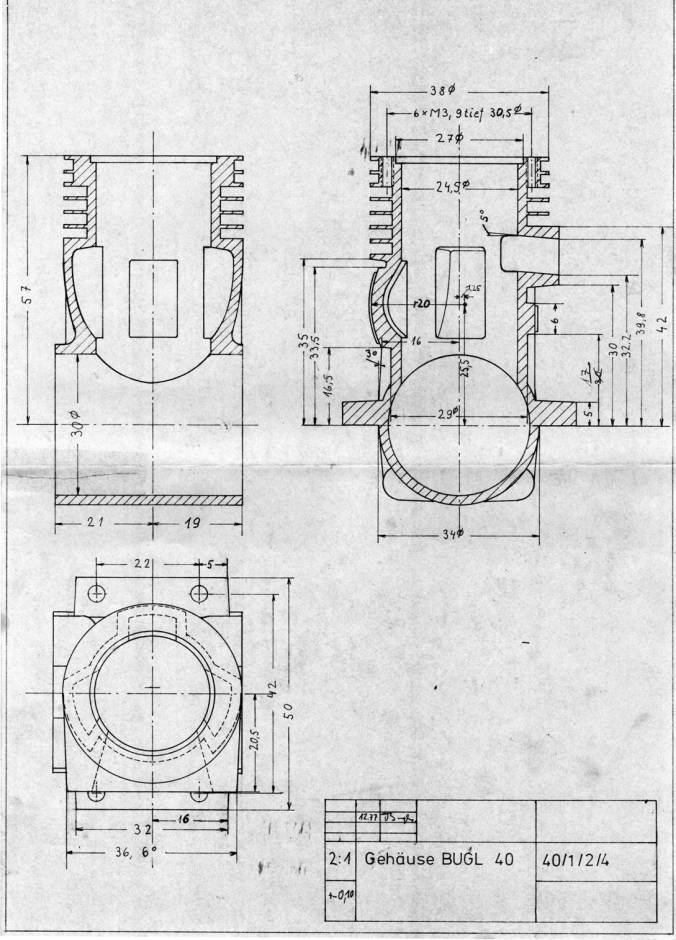

Paul was a perfectionist in his machine work I will never forget when teams were fitting cowling around the wheel to reduce drag, at the next competition Paul turned up with a fully machined metal one fitted to the leg, it was only just wider than the wheel we all just looked at amazement. Paul started design on his Bugl 40 and 60 RC motors but non were ever completed, strange if you look at the photo “Made in West Germany” how times have changed. Paul did keep a small black book which he recorded the motor serial numbers and to whom they were originally sold this also had RPM figures for each motor, one day when we was in the woods testing the wind blew open the page to Baumgartner ask no more. The MK11 motors had a coloured motif on the side of the motor and to the best of my knowledge the production motors were black, Austrian and friends red and any motors that were blue belonged to Paul this was his colour same as on the “MOSKITO” model even the propellers made for Paul by Bartels were blue. I will not go into technical details of these motors as these will be covered by Luis in his chapter.

Baumgartners retract model with MK11 and red motif.

Bugl 40 and 60 crankcases ready for machining.

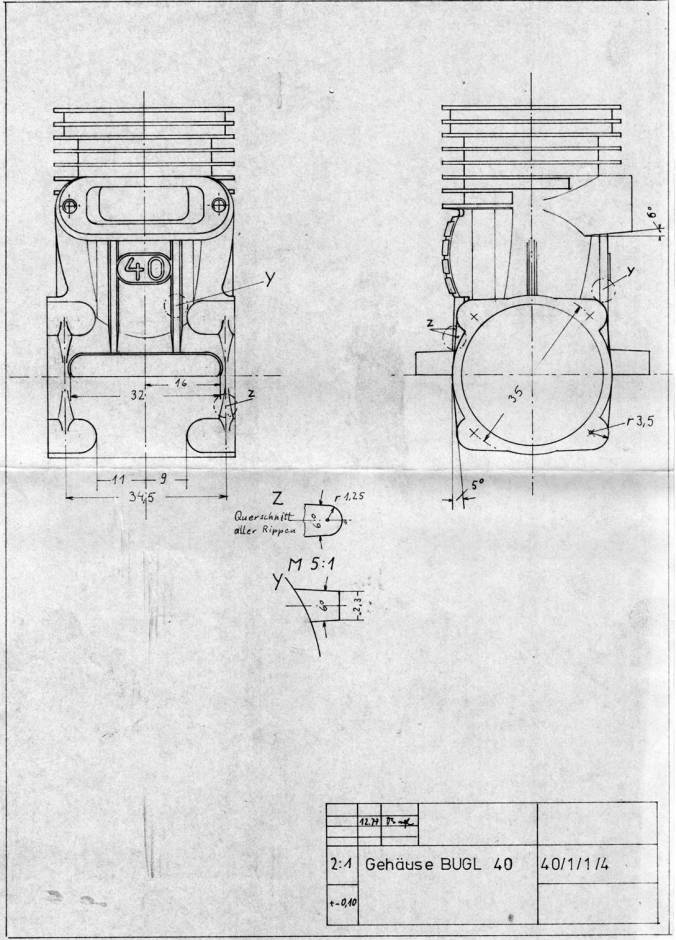

Bugl 40 case drawings

Conrods crankshafts and pistons for 61 and 40 motors.

Feb 2021 just received this information from Dave Bennett from Bristol (UK).

He purchased a Bugl 61 and a Bugl 40 both were complete and ready to go from a contact in Germany, the 61 has a serial no F007 and the 40 is unmarked, the 40 was completed by MVVS apparently under the guidance of Jurgen Bartels.

E

E

Paul’s blue models with prop.

Trade mark of Paul Bugl.

Transfers supplied with each motor which I had made.

Paul would always show us all his latest ideas and planned production methods, all manufacture was to be undertaken in the basement his main workshop, most of his machinery was purchased from a sales outlet and then duly stripped and rebuilt to his high standards, even the new Colchester Lathe was stripped and rebuilt as there was to much play in the head stock bearing, what a man, with typical German efficiency he had jigs and written instructions for the manufacture of each part, the idea being engineers could make these parts without any supervision leaving Paul to continue with design work, however Paul did employ some engineers but always found they had no interest in making these parts to his high standards. Every time we met Paul and Hans Straniak we always had a great time in competition and socially unfortunately this did not last however I am still in contact with Hans. This now ends my memories of “Paul” what would have happened if he was still alive, one will never know.

Ronnie Tribe

Austrian Modelling Magazine

Rest in peace

December 19 more photos added.

Feburary 2021. Conclusion or Endgame.

Bugl 61 and 40.

Many people over time have asked what happened to these motors. After some research I will now try and shed some light and clear the air on what happened.

Paul designed these two motors for full production, he set up a partnership with a person called (Muller) and Mullers machine shop was nearly ready to go into full production of both motors, unfortunately events overtook this with Paul passing away here ended the story of these motors, some of the unmachined crankcases found their way onto the open market which have been purchased by modellers to complete (no names know).

Some of these motors are now appearing on web sites the question is are they 100% a Bugl or not, research shows most of these motors have Webra front ends and internal parts using HP parts, the design for Paul’s motors used his bell valve induction attached to the crank pin with a bolt, cast conrod not machined, piston little end was design as per Bugl 15s and not a steel liner, if you have one of these motors you could have a look inside to find out what you have got.

So far I have found one person in England who has one motor of each and one person in Wales who has a 40 motor.

Two motors above

One motor above

The 40 motors look identical.